Rupture Discs

General description

Rupture discs are effective pressure relief devices. Berstscheiben-Schlesinger supplies

- Rupture caps

- High Pressure Rupture Discs

- Clean Gas/ Pharmaceutical Rupture Discs

- Composit-Ruptutre Discs for high and negative pressure

- Reverse / Double site Rupture Discs

- Signal transmitters

The Rupture Discs can be made of different materials (stainless steel, nickel, inconel, hastelloy, monel, titan, tantal)and also material combinations metal/PTFE. ATEX certificates optional.

Metal- / Composite-rupture discs

Rupture discs out of Metal/PTFE feature shatter-proof acition and therefore an ATEX certificate. Metal discs can be used for sensible application like Pharma-, or food & beverage industry.

- Materials: Stainless steel, nickel, inconel, hastelloy, monel, titanium, tantal, etc.

- Nominal widths: DN15 - DN900

- Rupture-pressure: 0,5- 4000 bar g

- Temp.: -196°C up to +480°C

- Arced or flat design

- ATEX certificate (optional)

Graphite-Rupture discs

Rupture discs avoid damages on vessel or under-pressure system and can be used for gasses and liquids. Graphite-rupture discs especially qualify for low-pressure applications

- Materials: Graphite and stainless steel (fitting)

- Nominal widths: DN25 - DN600

- Rupture pressure: 0,7- 28 bar g

- Temp.: -50°C up to +170°C

- Complete designs or exchangeable graphite discs with reusable fitting

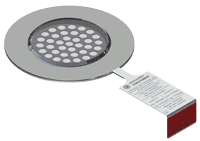

Signal transmitter

Signal transmitters are ideal additions to rupture discs and explosion panels by sending a signal when the pressure relief device activates. SCHWING supplies different designs with conductive foils or light barriers for different applications and demands.

- Sealings: Klingersil, Teflon, Gylon, Graphite

- Nominal widths: DN 20 - DN 600

- Temp.: -40°C up to +300°C