Filtration technologies

Filtration is a process to remove rigid or gel-like contaminations from liquid or gaseous media. A special form of filtration is coalescing, which seperates different liquids from gasesous media, resp. liquids from liquids (for example, water from fuel)

Filtration is achieved with re-usable (backflush-able) elements or exchangeable elements (Filter cartridges, Filterbags, etc.)

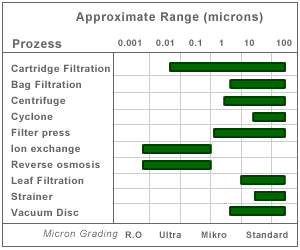

W.A.S. specialises in Microfiltration of gases and liquids between 0.01 - 1000 micron, primarily with exchangeable elements.

There are different Filtrationmethods for various applications:

Surface Filtration

Particles bigger than the micron graduation of the filtermedium cannot pass and stay at the filtersurface. Depending on the construction of the medium, we offer absolute or nominal Filterelements.

Surface (or pleated) elements are usually used for removing rigid particles out of a gas or liquid stream.

Examples for surface filtration are:

- Mesh filterbags

- Strainer or perforated baskets in diagonally pleated design

- Pleated filtercartridges feature a large filtration surface and therefore long running lifetimes, and depending on their design they are backflush- and reuse-able. For different applications and graduations there are different pleatings like V- or W-constructions

- Pleated metal cartridges

Depth filtration

Depth filtration means that the contaminant is hold inside of the filtermedium. The filtered medium itself finds its way through the filter by following the way of least resistance. This allows graded filtration troughout the whole element and also holds back gel-like contaminations. Depending on the construction of the medium, we offer absolute or nominal Filterelements.

- Felt filterbags, Multi-layerbags

- Microfibre bags

- Meltblown filtercartridges in absolute and nominal design

- Peco Facet PEACH Elements: PEACH is a patented filterdesign and are constructed with conical pleated and thermally bonded filtermedias in with different gradutations, featuring an exactly specified graduation of the element. PEACH technology is available for liquid and gas filtration

- Wound cartridge elements: a string of filtermedia is wound around a core tube, resulting in a very flexible filterelement for all kinds of applications. Different combinations of materials allow the useage with a variety of medias and process conditions.

- Acrylic resin filterelements are extremely endurable thanks to their rigid pore structure.

- (pleated) Sintermetal elements

Membrane filtration

Membrane filtration is a special form of surface filtration. The filtermedia is designed with a predefined pore-structure and allows a precise absolute filtration.

Examples for membranematerial are: Polyethersulphone (PES), Nylon, PTFE

Membranefilterelements allow a precise filtration down to 0.05 microne and are used for applications with high requirements regarding the quality of the filtered medium (for example filtration of germs)

A special form of membrane filtration is sterile Ventilation filtration with PTFE Cartridges, where the vessel has to be sterile through the whole draining process.

Filterefficiency

There are various terms for Filterefficiency (= performance to hold back contamination), often specified by the supplier. There is no binding directive, descriptions and values differ, depending on the method of filtration and supplier.

Below the most common definitions for describing filterefficiencies are listed:

- Nominal: 80% - 95% of the particles of the stated micron size or bigger are removed from the media

- Absolute: 98,0% - 99,99% of the particles of the stated micron size or bigger are removed from the media.

- Beta-Value ß: Based on the ratio of particles before and after the filterelement.

Beta Beta Beta Beta Beta |

50 |

= 98% |

( 1 - 1/ß) x 100 in % filterefficiency |